Norfolk Biomass Heat Meter Replacement

17 July 2024

Company Overview: Orka

Orka stands as a beacon of expertise in the building services engineering industry. With a diverse team boasting varied backgrounds, Orka delivers a comprehensive start-to-finish service, encompassing concept design, installation, and maintenance. This unified direction is the cornerstone of Orka's mission.

As industry influencers, Orka holds prestigious design and operational accreditations, particularly in innovative district heating systems. The company's relentless focus on improving efficiencies and achieving high levels of customer satisfaction sets it apart in the market.

Project Overview

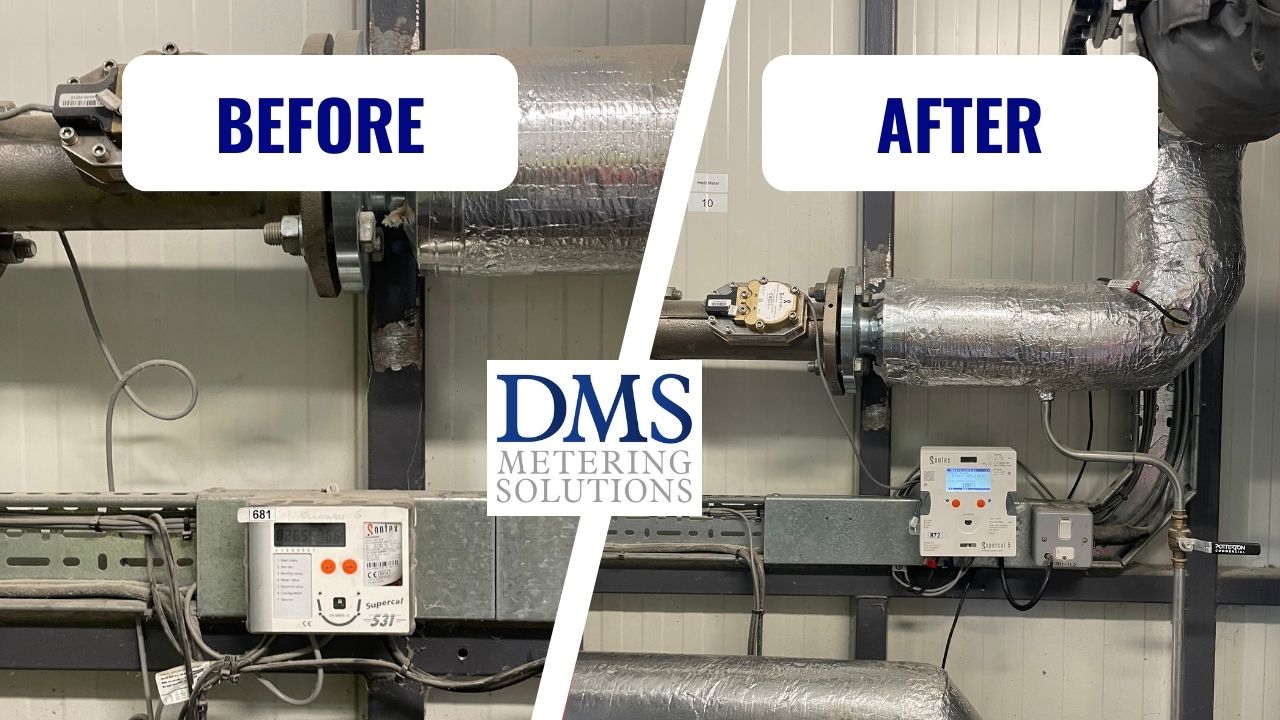

Project Name: Norfolk Biomass Heat Meter Replacement

What We Supplied

Supplier: DMS Metering Solutions

Equipment Supplied: 179 Sontex Supercal 5s Heat Meters

Additional Services Provided: Heat Meter training (Lunch n Learn)

The Challenge

The primary challenge in the Norfolk Biomass Heat Meter Replacement project was the need to extend the Renewable Heat Incentive (RHI) revenue for an additional 10 years. The existing heat meters had reached the end of their operational life, necessitating a reliable replacement to ensure continued compliance and revenue generation under the RHI scheme.

The Solution

To address this challenge, DMS supplied 179 Sontex Supercal 5s heat meters, renowned for their accuracy and reliability. These meters were chosen to replace the old units, ensuring seamless integration with the existing infrastructure. Additionally, to enhance the functionality and integration of the new heat meters, they are planning to incorporate Modbus/BACnet connectivity modules later in the project. These modules will enable the meter data to be integrated with the control systems within each biomass plant room.

Implementation and Training

DMS not only provided the energy/heat meters but also delivered comprehensive training. This training empowered our team to handle the commissioning process independently, ensuring that the new meters were correctly installed and fully operational.

Additional Information

The training received from DMS was exceptional, equipping our team with the necessary skills and software to commission the equipment effectively. This self-sufficiency in commissioning allowed us to maintain flexibility and control over the installation process, ensuring that each meter was correctly allocated and installed without the added complexity of managing pre-commissioned units.

Conclusion

The Norfolk Biomass Heat Meter Replacement project exemplifies Orka's commitment to leveraging cutting-edge technology and industry expertise to meet client needs. By partnering with DMS, we successfully replaced outdated heat meters, securing an additional decade of RHI revenue and enhancing the overall efficiency and control of the biomass heating systems